News & Events

September 30, 2020

Health Canada Authorization Update: Mechanical Ventilator Milano Project

September 30th, 2020:

The Canadian members of the Mechanical Ventilator Milano (MVM) consortium are pleased that Health Canada has given Vexos Inc. of Markham, Ontario authorization for the use of the MVM ventilator.

This paves the way for Vexos to manufacture and supply 10,000 ventilators as part of a national, made-in-Canada, effort to treat patients most severely affected by the COVID-19 virus. Vexos will now start shipping the MVM ventilators to the Government of Canada.

This authorization by Health Canada acknowledges and rewards the ingenuity and tireless efforts of Vexos and the entire MVM consortium.

“This achievement originated with particle physicists who in a matter of days shifted their research from dark matter to inventing a new ventilator, a leap which demonstrates the flexibility and ingenuity of dedicated people who reacted in a crisis to apply their skills to saving lives. We worked cooperatively with physicists, engineers, and health care professionals around the world to develop this life-saving device, and I am happy that Canada has now given Vexos approval to allow these ventilators to be sent where they are needed.”

Dr. Art McDonald, leader of the Canadian arm of the MVM Consortium, Queen’s University Professor Emeritus, and co-recipient of the 2015 Nobel Prize in Physics:

May 12th 2020: FDA EUA Update:

The US Food and Drug Administration (FDA) has granted Emergency Use Authorization to the ventilator designed by an international collaboration of nuclear and particle physicists, the Mechanical Ventilator Milano (MVM). This is an important step in getting the MVM ventilator to patients around the world who are suffering the respiratory effects of the COVID-19 virus.

Canada’s particle physics community and their collaborators in medicine, engineering, computer sciences, manufacturing and fund-raising have magnificently demonstrated their flexibility and adaptability in committing their knowledge and skills toward solving a most pressing global problem.

“We in Canada have been very pleased to participate in the development of this new ventilator design.” says Dr. Art McDonald, “For me personally it has been wonderful to work with an international team covering such a broad range of expertise, working extremely hard to save lives in these difficult times. Everyone is very happy that their talents can make a difference, a true humanitarian spirit.”

Dr. Arthur McDonald, who is leading the Canadian team with participation from TRIUMF, Canadian Nuclear Laboratories, SNOLAB and the McDonald Institute, says the project has received extraordinary support, “Even in a time of crisis, everyone involved in this project is working flat out, with a strong emphasis on medical safety requirements, using their specialized skill set to create this ventilator. I am encouraged to see Canadian researchers, manufacturers and clinicians working together to help COVID-19 patients.”

This recent FDA approval validates the design and will be helpful for the Canadian manufacturing companies Vexos and JMP Solutions who will seek Health Canada authorization for their final product based on the international design.

April 7th 2020:

Canadian astroparticle physicists, engineers, project managers and their colleagues across the country are working with Italian and other counterparts around the world to develop an easy-to-manufacture, medical ventilator. The devices are desperately needed to keep the most severely stricken COVID-19 patients breathing long enough to recover from viral lung infection.

Canadian physicists have been working with a large contingent of Italian colleagues to design a prototype of the Mechanical Ventilator Milano (MVM). The project was initiated by Dr. Cristiano Galbiati of the Global Argon Dark Matter Collaboration in Italy, who recognized the need for additional ventilators early in the pandemic and received government permission to develop a first prototype at the SAPIO Life s.r.l. ventilator repair and support center in Vaprio d’Adda, near Bergamo.

The MVM project’s goal is to deliver a simplified device that can provide assisted and recovery ventilation. By designing it with readily available off-the-shelf components, the MVM could be manufactured rapidly in order to meet projected surges in demand.

The collaboration continues to grow and now spans more than 50 public and private organizations. It includes personnel from Canadian Nuclear Laboratories (CNL), TRIUMF, SNOLAB, St. Michael’s Hospital, and Queen’s University where Dr. Art McDonald has been coordinating the Canadian team. Italian contributors come from Gran Sasso Science Institute, 10 laboratories of the Italian National Institutes for Nuclear Physics (INFN) and Health (ISS) and more than a dozen universities and private-sector firms. Other European experts include those from CERN, CNRS-IN2P3, CIEMAT, the Max-Planck Institute and AstroCent. U.S. contributors include two Department of Energy national laboratories and five universities.

To facilitate rapid certification of the final design, additional direction is being provided by Health Canada, the US FDA, the US Air Force and the Italian Istituto Superiore di Sanità and Consiglio Tecnico Scientifico della Protezione Civile. At the same time, the MVM Consortium is making sure that design and background knowledge is in the hands of a manufacturing partnership to allow them to gear up quickly for production. Other teams across Canada and around the world are doing similar work and are using a variety of go-to-market strategies to get more ventilators in the hands of doctors as soon as possible.

The MVM project is developing in an open innovation framework to encourage collaboration in design and testing. This will also minimize the time required to get the ventilators manufactured and distributed to the people who need them. The team regularly updates the design specification and description in arXiv.or

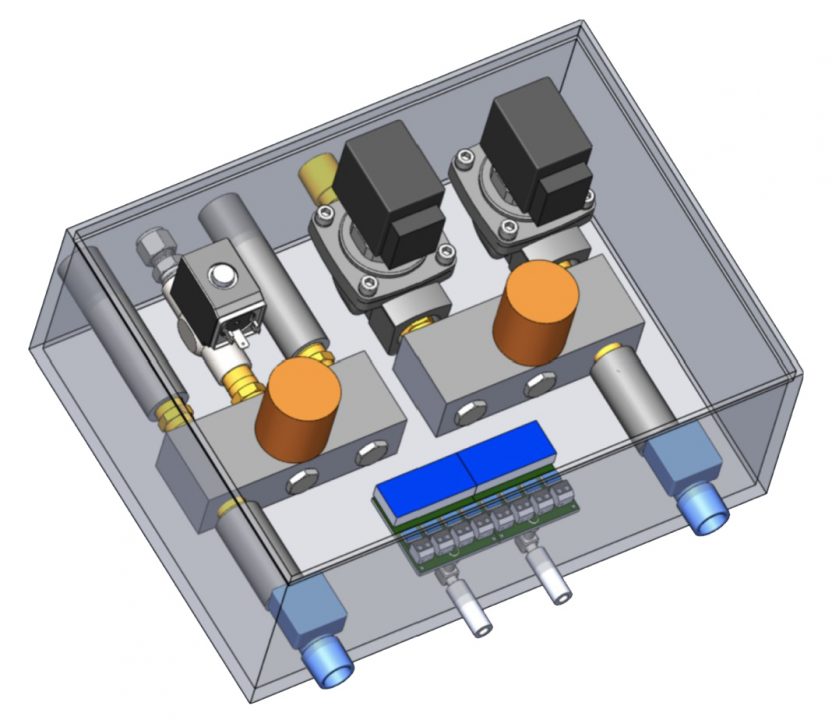

Left: A March 31 iteration of Mechanical Ventilator Milano (MVM) controller base assembly with connecting ports. Image provided in the arXiv paper at: https://arxiv.org/abs/2003.10405

Above: Christoforo Ienzi, a mechanical design technologist with CNL’s Mechanical Equipment Development Branch working on 3D CAD design of the MVM ventilator at his temporary home office. Christoforo is also 3D printing face shields as part of another one of CNL’s efforts to support the medical community during the pandemic.

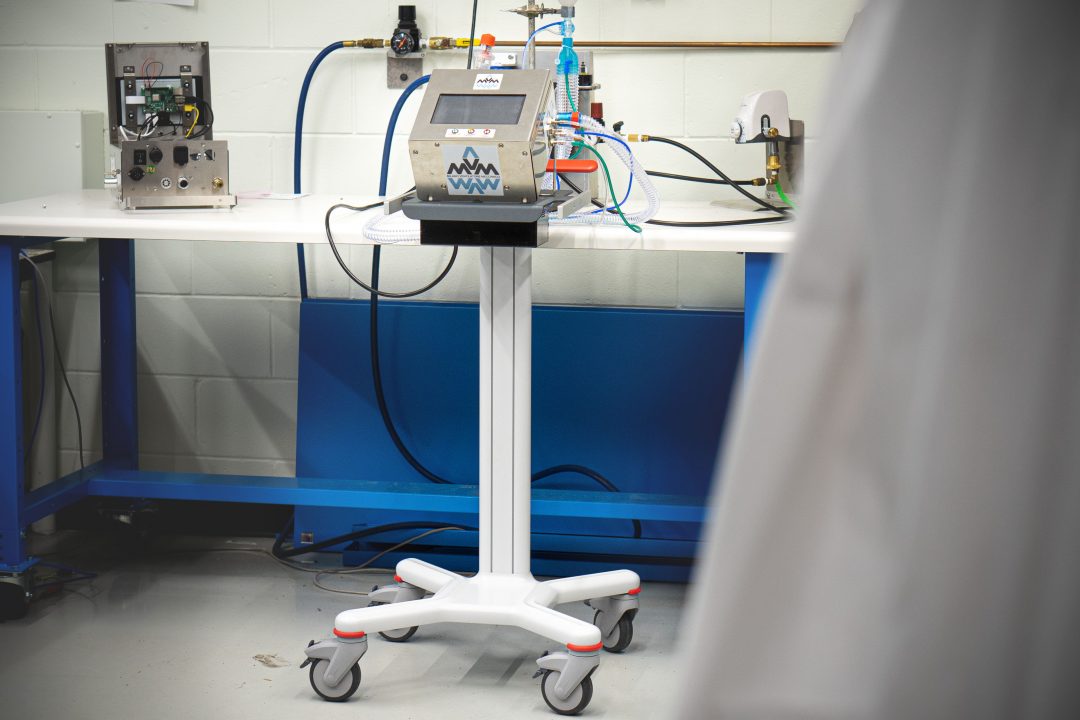

Above: Testing performance of an early prototype with a breathing simulator at Ospedale San Gerardo in Monza, Italy.